There are thousands of reasons for the failure of the Hydraulic Rubber Hose, but with proper precautions, the most common failures can be avoided. The following Twin Welding Hose Manufacturer will explain it to you once.

1. Fluid compatibility Incompatible fluids will cause deterioration, swelling and delamination of the inner rubber layer of the hose assembly. In some cases, the inner glue layer may also be partially destroyed. The hose must be compatible with the fluid being transferred. It should be ensured that the fluid is not only compatible with the inner rubber layer, but also compatible with the outer rubber layer, joints and even O-rings.

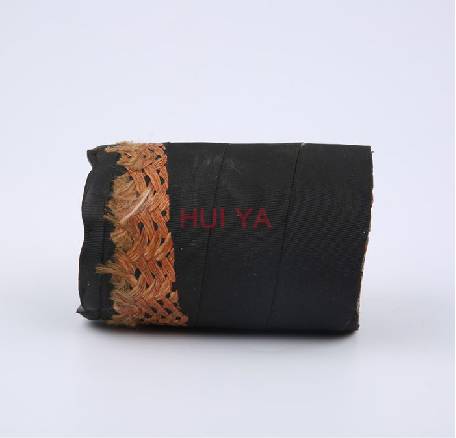

SAE 100R3 hydraulic rubber hose

2. The inner rubber layer of the dry air/old air hose may cause many tiny cracks due to old or dry air. Sometimes, this type of failure is difficult to find because the hose can still remain flexible, but there will be signs of external leakage.

To avoid problems with dry or stale air, you should confirm that your hose rating is suitable for extremely dry air. For these applications, it is best to choose hoses with PKR or EPDM rubber materials.

3. Minimum bending radius If the minimum bending radius is not met, the hose assembly may fail relatively quickly.

In vacuum or suction applications, if the bend radius is exceeded, the hose may become flat in the bend area. This will hinder or restrict the flow of media. If the bending is too severe, the hose may be kinked. In order to prevent the smallest bending radius hose failure, the recommended bending radius should be carefully checked.

4. Worn hydraulic hoses need to go through harsh environments every day, and their effects will eventually appear on the hoses. If the inspection is not performed regularly, wear and tear may cause the hose assembly to rupture and leak. If the hose has excessive friction with external objects or even another hose, it will wear off the coating on the hose and eventually wear the reinforcement layer.

Properly assembled and installed hoses will have a longer life, thereby reducing downtime and maintenance costs.

If you are interested in the Hydraulic Rubber Hose. Welcome to us.

Copyright © Hengshui Huiya New-Mat Technology Co., Ltd. All Rights Reserved Sitemap